The world of 3D printing is expanding at a significantly fast pace. Estimates suggest that the global market size of 3D printing—products and services—will grow three times between 2020 and 2026. Valued at US$12.6 billion in 2020, the market could grow to over US$37 billion by 2026.

The surge in the market of applications is ably supported by the space where innovation happens—both at the level of institutions and businesses/companies. Large US tech companies, for instance, have been highly active with 3D printing—as evident from the number of patents they’ve published since 2010. General Electrics, for example, has published as many as 342 patents between 2010 and 2019.

However, the realm of 3D printing has always faced the crucial question of real-life applicability. While it has always been a scientifically exciting and enticing space to explore, many have asked, ‘How realistic is it?’

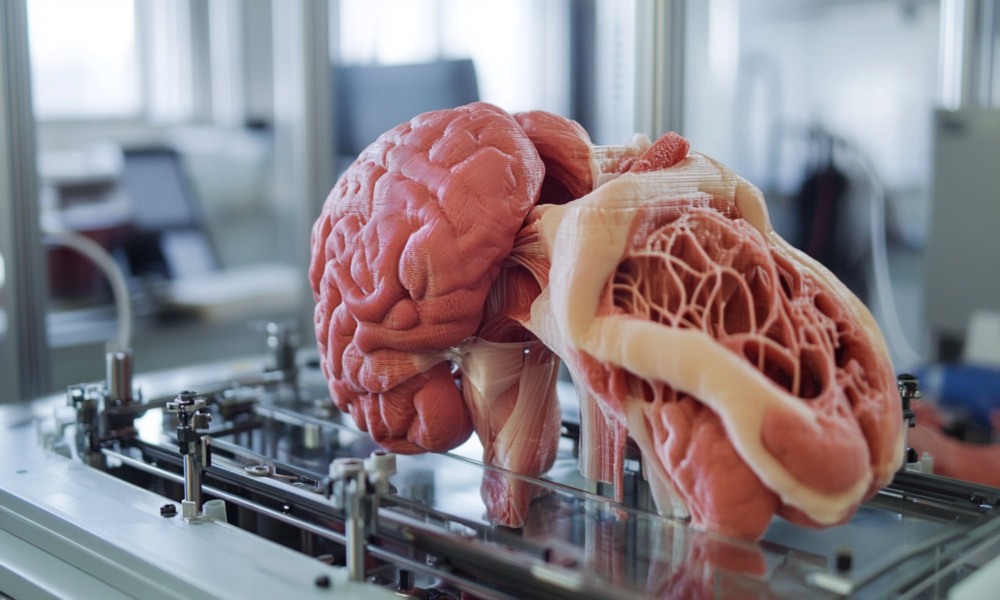

Recently, a successful experiment showed how real it could potentially be when a research team at the University of Virginia School of Engineering and Applied Science developed what could be the template for the first building blocks for human-compatible organs printed on demand. In the coming segment, we look into the experiment and what it achieved in greater detail.

Biomaterials With Controlled Mechanical Properties Matching Those of Various Human Tissues

The experiment was led by Liheng Cai and Jinchang Zhu. Liheng Cai is an assistant professor of materials science and engineering and chemical engineering, and Jinchang Zhu is his Ph.D. student.

The bioprinting method they followed is called Digital Assembly of Spherical Particles (DASP). This technique deposits biomaterial particles in a water-based supporting matrix to build 3D structures that offer a conducive environment for the cells to grow.

In publishing their findings in the journal Nature Communications, the scientists named the report ‘Voxelated bioprinting of modular double-network bio-ink droplets.’ The term Voxel stems from the fact that the printing process follows how ‘voxels’—the 3D version of pixels—construct 3D objects.

While explaining the breakthrough their research empowered the scientific community with, Jinchang Zhu had the following to say:

“Our new hydrogel particles represent the first functional voxel we have ever made. With precise control over mechanical properties, this voxel may serve as one of the basic building blocks for our future printing constructs.”

In his attempt to be more specific for the common user, Zhu highlighted the standout qualities of their technique compared to other bioprinting methods. He stressed the element of ‘Control’ in their technology, which made it possible to print organoids.

These organoids were nothing but 3D cell-based models that could function as human tissues. It could be leveraged to study disease progression in our ever-evolving search for cures.

A Big Leap Compared To Existing Bioprinting Technologies

Zhu termed their innovation a ‘big leap’ compared to existing bioprinting technologies because it was ‘sturdy and cell-friendly.’ The polymer hydrogel particles used in the experiment could mimic human tissues by tweaking the arrangement and chemical bonds of single-molecule monomers, which link together in chains to form networks.

In comparison with other similar solutions, the solution offered by Cai and Zhu also came out to be less toxic and more biocompatible.

The team also achieved significant improvements in their use of the bioprinter. The multichannel nozzle they designed could mix hydrogel components on demand. It helped solve the challenge arising from superfast cross-linking, which transformed liquid droplets into elastic water-swollen gel within 60 seconds.

The DASP technique removes this bottleneck by depositing large droplets from a narrow and fast-moving nozzle into the matrix, immediately suspending them. In a way, it solves a core issue about the space of soft matter science and 3D bioprinting: the precise manipulation of viscoelastic voxels. In summarizing the achievement, Cai said:

“We’ve now laid the foundation for voxelated bioprinting. When fully realized, DASP’s applications will include artificial organ transplant, disease and tissue modeling, and screening candidates for new drugs. And it probably won’t stop there.”

As we have already seen, innovations around 3D bioprinting have been ongoing for a long time. Therefore, it is quite obvious that many reputed companies have adopted this technology. In the following segments, we look into two companies that have been facilitating this space in medical science and healthcare technology.

#1. Northwell Health

The company claims to be ‘100% devoted to being the first health system to 3D print your cure’. One of Northwell Health’s most crucial interventions in this area has been in prosthetics.

The company 3D-printed an amphibious prosthetic limb. The solution is a Fin that allows the amputee to enter and exit the water without changing prosthetics.

The fin’s benefits include its use of state-of-the-art carbon fiber materials and the leveraging of an ergonomic shape to ensure durable and efficient movement. Northwell used carbon fiber-enhanced nylon to print the fin, which was all about strength and flexibility. Moreover, its durability made it fit for use on land and in the water.

The fin had unique material dynamics. It featured conically shaped holes that could control the amount of water passing through it. The design and arrangement of the holes allowed natural drag and propulsion in the water. The number of holes was adjustable to the specific needs of the amputee.

Northwell Health has long been a champion in developing 3D-printed, detailed models of body parts to help surgeons better plan operations. The company could realize the potential of 3D printing before it became such a thriving trend.

In a quote that dates back to 2018, Todd Goldstein, director of the 3D Design and Innovation Center at Northwell Health, had the following to say:

“The use of 3D printing in medicine allows us to pull the patients’ anatomy off of a computer screen and put it into the physician’s hands. This type of technology is a game changer for all parties involved, as it allows for physicians to better visualize the pathology, allows for patients to truly see what treatment is needed, and allows for more precise, patient-specific treatments across almost all specialties.”

In 2023, Northwell Health registered revenue of US$16.9 billion and an EBITDA margin of 6.3%.

#2. Psyonic

Another company that has been doing remarkable work in this field is Psyonic. Ability Hand, Psyonic’s flagship product, is the world’s fastest and first touch-sensing bionic hand. Promised to restore life and mobility to where they were, PSYONIC leverages 3D printing to efficiently prototype, increase affordability and access, and enhance durability and impact resistance.

Psyonic has added significant value to its solution by incorporating sensors in the bionic hand’s fingertips that detect pressure when the wearer is gripping an object and send a vibration to the arm to communicate that sensation.

Consequently, the hand user can feel the action and work with the most delicate objects with ease, comfort, and seamlessness. Its toughness makes it capable of handling blunt force impact without breaking. It is also water resistant and comes with a variety of grip patterns for use throughout the day.

Ability Hand offers 32 grip patterns in total, of which 19 are predefined and available for use. It is lightweight, weighing 490 grams. It is multi-articulated, with all five fingers ready to flex and extend, and the thumb is capable of rotating electrically and manually.

It can be charged with a USB-C in an hour. It is cross-compatible and works with most third-party EMG pattern recognition systems, EMG direct control systems, linear transducers, and force-sensitive resistors.

According to the latest available funding information, Psyonic’s crowdfunded equity campaign has raised more than $1 million to date.

Evident from these examples of 3D-printed human body parts is that, realistically, 3D printing human organs is not a far-fetched dream. While we have already discussed one of the most significant breakthroughs in this field recently, we will explore more relevant research to understand the vast potential of the future.

Click here to learn about a new technique that allows for 3d printing a functional brain tissue.

The Future of 3D Printing: As Close to Reality as it Could Get

The use of hydrogel inefficiently in the production of 3D-printed organs has some history. A 2022 research report cited the instance of a study team led by Professor Thomas Scheibel at the University of Bayreuth successfully producing a “bio-ink” or hydrogel through the mixing of spider silk with mouse fibroblast cells using 3D printing.

The gels could transform rapidly from a fluid to a solid state when flowing through the printer head onto an extrusion surface. The knowledge was found to be used in replicating cardiac muscle tissue using spider silk scaffolds and cardiomyocytes.

A 2023 report that comprehensively investigated the reality of using 3D printing to replicate human organs claimed it to be a ‘soon-to-be reality.’ It cited many instances that indicate a promising future in all probable implications.

For example, in 2022, in San Antonio, Texas, Dr. Arturo Bonilla could implant an outer ear on a 20-year-old woman—born without one—by constructing the right ear in the exact shape and size of her left. The case was immensely crucial as it was the first instance where the implanted ear was the product of a 3D bioprinter using the woman’s cartilage cells.

Poland-based researchers were also able to print a functional prototype of a pancreas with stable blood flow. The experiment was conducted on pigs and observed for two weeks. Meanwhile, efforts to adapt the techniques for human lungs were also underway. Michal Wszola, the creator of Bionic Pancreas, and United Therapeutics Corporation 3D printed a human lung scaffold with 4,000 kilometers of capillaries and 200 million alveoli (tiny air sacs) that could exchange oxygen in animal models.

The Wake Forest Institute for Regenerative Medicine scientists developed a mobile skin bioprinting system. They believe that soon, it would be possible to roll the printer right to the bedside of a patient suffering from a non-healing wound, such as a burn, scan and measure the wound area, and 3D print the skin, layer by layer, directly onto the wound surface.

Professor Tal Dvir is the director of tissue engineering and regenerative medicine at Tel Aviv University in Israel. His level has spearheaded the project of a 3D-printed “rabbit-sized” heart, which has cells, chambers, the major blood vessels, and a heartbeat. While speaking about the invention and its potential for the future, Dvir had the following to say:

“We’re now working on the pacemaker cells, the atrial cells, the ventricular cells. It looks good. I believe this is the future.”

Health experts believe that human civilization’s capability to 3D print organs would help the 106,000-person waiting list for organ donations. Each day, 17 patients die while waiting. Being able to 3D print human organs would save many lives.

According to Mark Skylar-Scott, an assistant professor in the Stanford University Department of Bioengineering:

“The field has moved very quickly over the past two decades, from printed bladders to now highly cellular tissues with vessels that can be connected to a pump—and complex 3D models that resemble heart components with integrated heart cells.”

It is now almost certain that 3D-printing human organs will revolutionize our treatment procedures and care systems. However, it would have to overcome some challenges.

For instance, it would have to be more stress-resistant. Production and manufacturing would have to be more inclusive in terms of the compatibility of raw materials. It would have to become energy efficient so that it can be scaled up faster.

It would have to get rid of the volatile organic compounds emitted by 3D printers that are often carcinogenic and toxic and can cause serious health problems like organ damage, throat irritation, and nausea. Finally, it would have to be cost-effective and affordable to benefit a large chunk of our under-treatment population worldwide.

Click here for a list of most promising 3d bioprinting stocks.