Batteries To Electrify The World

Battery technology is changing the world in countless ways. The most obvious example of this is EVs, but advanced batteries are also the driving force behind the growing importance of drones and other futuristic innovations like maglev, Hyperloop trains, and even mass drivers to conquer space.

They are also going to be essential in turning our power grid green by smoothing the energy production curves of solar panels in the evening and wind turbines on windless days.

Source: Statista

For now, battery technology has been carried by lithium-ion technology, a discovery so essential that it won the Nobel Prize in Chemistry in 2019 (you can read more about the history of its discovery in our dedicated article).

Still, lithium-ion batteries have one serious limitation. Over time, spikes of metallic lithium, called dendrites, grow a little at each charge/discharge cycle. This can lead to the dendrites piercing the battery’s components, creating a shortcut. The danger of such a shortcut is further compounded by the fact that lithium-ion batteries use flammable electrolytes, making battery fires very hot and hard to put out.

This is a problem shared to some extent by all lithium-based batteries, including LFP (Lithium-Ferrum-Phosphate) chemistry. At least until now.

Source: Nobel Prize

For a long time, the alternative has been thought to be either an entirely different chemistry like sodium-ion or a different battery concept, especially solid-state batteries, which do not use electrolytes at all.

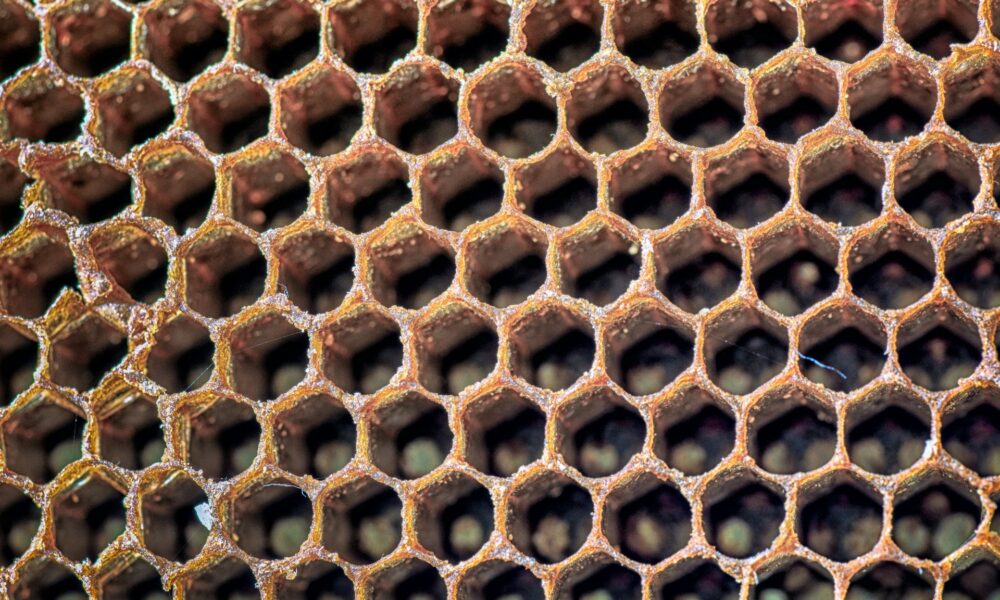

This might not be true after all. The leading battery manufacturer CATL has announced that a new “honeycomb” design can create batteries with zero signs of degradation after 5 years of intensive use.

This design could be used to create batteries as energy-dense as solid-state batteries while still using mostly current technology.

Honeycombs To Harbor More Power.

A key reason batteries degrade and grow dendrites is that the material contracts and expands during each charge/discharge cycle when the lithium ions enter the anode’s matrix.

Managing contraction/expansion is also one of the key issues that has hindered the development of solid-state batteries. CATL claims to have found a solution by developing a complex honeycomb-like structure for its anode material.

The idea is not entirely new, as it was already proposed by researchers, like for example in a 2020 scientific paper titled “Stretchable lithium-ion battery based on new micro-honeycomb structure”.

Source: Phys.org

The company announced a new LFP (lithium-iron-phosphate) battery that can add 600km of range in just 10 minutes. In total the driving range could be above 1,000 km (600 miles), totally removing all “anxiety range” for future EV owners.

Overall, this means 1 km worth of range can be charged every second and a full charge for 1,000km will take 16.6 minutes.

New Density Record

This impressive range is possible because “the Shenxing battery system’s energy density surpasses the 200 Wh/kg threshold for the first time, reaching 205 Wh/kg”.

This was achieved thanks to a “honeycomb” structure that essentially keeps the material in the right place, avoiding cracks and contraction during charging.

The company is, of course, relatively secretive over the details of its manufacturing process, as battery tech is maybe one of the most competitive spaces in the world currently, notably with BYD’s next generation of blade batteries expected to come out at 190 Wh/kg.

Manufacturing Secrets

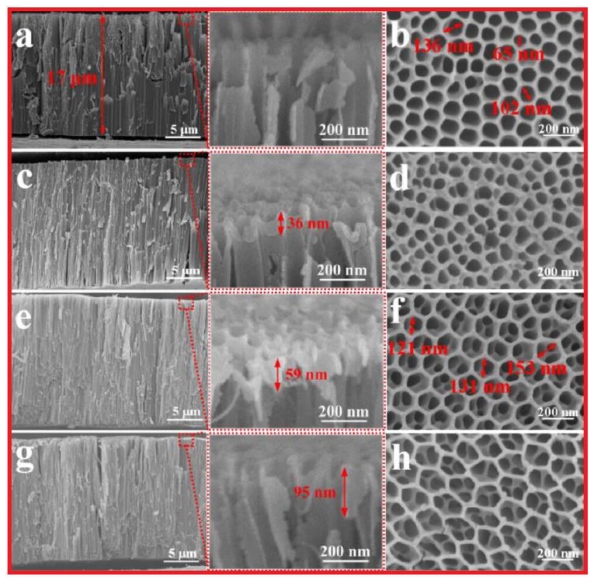

We do know that they used something called “granular gradation/nanometer encapsulation,” which can place every nanometer particle within the cell in the right spot. They also mentioned “fast lithium-ion conductive coating” to speed up the energy transmission between the 2 poles of the battery.

CATL factories are highly automated and can produce one of the new LFP batteries every 1 second in its flagship factory.

From a 2021 scientific paper, we can learn some of the key advantages of honeycomb shapes, notably low density and high out-of-plane compression and shear properties (resistance of materials to forces acting in parallel but opposite directions).

The honeycomb graphene arrangement effectively prevents silicon nanoparticle agglomeration, improves electrical conductivity, and decreases Li+ transport resistance.

While it is not clear how CATL did it, some of these methods are known; for example, successive thermal and chemical treatments with carbon and acid can create a nano-honeycomb structure.

Source: Chemistry Europe

Source: Chemistry Europe

Other Improvements

In battery tech, every improvement counts as they can compound each other to make the battery denser. In turn, this reduces the volume of battery needed for a certain mileage. This then reduces the total weight, further increasing the range and/or the batteries needed.

Parallel to its honeycomb structure, CATL also announced a few other improvements. One factor in boosting CATL’s new battery density is optimized cell-to-body technology (CTB), which optimizes the space the battery takes in the battery pack. This led to a volume efficiency improvement of 7%.

Other features are ultra-high cooling efficiency high-voltage box, reducing power consumption by the cooling system. An AI intelligent battery management system algorithm also ensures the safety of the battery.

Charging Infrastructure

The infrastructure to charge EVs has been a limiting factor for a long time, mostly because you need a network as dense as currently existing fuel stations to avoid long waiting times and gaps in the charging network in remote areas. However, another issue is creeping in, which is the capacity of these charging stations.

As batteries become more capable of handling massive power loads and quick charging, the charging stations themselves need higher capacity. The quick 16-minute charge for 1,000 km requires a 4C charging process, which itself requires a massive 400 kW charging power for a 100 kWh battery.

For this reason, CATL announced at the time that it was entering the charging infrastructure market. It will start building the Shenxing Superfast Charging Network in China, collaborating with industry-leading partners like Star Charge, YKC, and Shudao New Energy.

Overall, it is planning 600 service outlets covering 271 prefecture-level cities in 31 provincial-level regions. The provision of batteries, charging networks, and services like battery inspection and maintenance aims to create a closed-loop ecosystem.

Beyond LFP & EV

Utility Scale

CATL is increasingly active in the utility-scale battery market, with seemingly a renewed interest in using lithium-based chemistry, after considering sodium-ion instead.

Most notably, it declared that a pilot project, using the TENER containerized battery system, has demonstrated zero degradation in capacity after a full 5 years of operation.

Source: Sustainability Environment

The honeycomb structure is likely becoming a central part of CATL’s battery architecture. While not explicitly stated as such, this is probably what CATL referred to when talking about TENER:

To realize TENER, the company used an SEI with biomimetic ion channels and high stability, together with self-assembled electrolyte technologies creating what it calls an “ageless energy storage system.

Based on state-of-the-art technology and extreme manufacturing capabilities, we have solved the challenges of highly active lithium metals […], which effectively helps prevent the thermal instability caused by the oxidation reaction,”

This unprecedented performance of TENER could completely change the equation for fixed battery storage, as no degradation means a much-improved safety profile. It also changes the calculus of amortization by promising a much more lasting battery pack, a key point for utility companies.

So other chemistry could still win this market, as we discussed in “The Future Of Energy Storage – Utility-Scale Batteries Tech”. But it is also possible that lithium ends up winning the utility market, which is much larger than even the gigantic and growing EV market.

Condensed State

It is also possible that honeycomb structures are behind the “condensed state” battery revealed in 2023 and expected to be commercialized soon.

These lithium batteries (not LFP) are claimed to display a 500 Wh/kg energy density, or 2.5x larger than the recently announced LFP batteries.

No price tag has been announced for this project, so the upcoming line-up from CATL seems to be as such:

- Condensed state at 500 Wh/kg for high-end EVs and even maybe new markets like electricity-powered aircraft.

- Advanced LFP at 200 Wh/kg for medium-price EVs, with a 1,000 range chargeable in 16 minutes with the right charging infrastructure.

- Sodium-ion for low-cost EVs with a smaller range.

It is not clear where solid-state batteries would fit in that mix. Some investors might even be concerned that the 1st generation of solid-state design could be outcompeted by the scale of production of CATL’s advanced LFP and condensed-state batteries.

Source: Nature

Investing In Advanced Battery Technologies

Batteries are at the center of the trend of electrification, itself a major multi-trillion-dollar endeavor looking to remove fossil fuels from our power sources.

You can invest in battery-related companies through many brokers, and you can find here, on securities.io, our recommendations for the best brokers in the USA, Canada, Australia, the UK, as well as many other countries.

If you are not interested in picking specific battery companies, you can also look into biotech ETFs like Amplify Lithium & Battery Technology ETF (BATT), Global X’s Lithium & Battery Tech ETF (LIT), or the WisdomTree Battery Solutions UCITS ETF, which will provide a more diversified exposure to capitalize on the growing battery industry.

Advanced Battery Companies

1. CATL (300750.SZ)

We talked already of CATL technological lead. The company is the global leader in battery manufacturing, producing more than half of the global battery volume. It is present at every step of the battery manufacturing supply chain and is a leader in battery technology.

This is true for lithium-ion batteries, where the company has been a long-established leader for a long time. Now it looks small in comparison to the latest announcement.

CATL has also announced in the past impressive progress on multiple other battery types :

Source: CATL

Source: CATL

CATL has also invested 3.25B in battery recycling capacities in China. CATL has notably achieved a remarkable recovery rate of 99.6% for nickel, cobalt, manganese, and 91% for lithium.

Thanks to its scale, focus, and R&D achievements, CATL is likely to be at the forefront of battery innovation, manufacturing, and recycling.

This makes it a key partner for EV manufacturers, including Tesla, NIO, Ford, Stellantis, etc, with Hyundai recently added to CATL growing rooster of strategic alliances.

In addition, the lessons learned in one chemistry can be applicable in another, so we might see soon honeycomb or condensed-state sodium-ion batteries for example. The economies of scale in producing half of the world’s batteries are also likely applicable to the whole company, regardless of the specific technology used in an individual product.

2. BYD (BYDDY)

A long-time challenger of Tesla in the EV market, BYD has become a serious competitor not only for Tesla but for virtually all automakers.

The company evolved from its origin as a supplier of lithium-ion phone batteries to selling almost as many EVs as Tesla in China (the world’s largest EV market) and being the best-selling EV in Thailand, Sweden, Australia, New Zealand, Singapore, Israel, and Brazil.

BYD is a large part of why China suddenly became the world’s largest car exporter in 2023, surpassing Japan. The company’s aggressive overseas expansion is also carried by new factories, like in Hungary.

And with the release of $10,000-$12,000 cars like the Seagul, using sodium batteries, a whole new market might open for BYD EVs.

Source: By User3204 – Own work, CC BY-SA 4.0,

Still a battery manufacturer at its core, BYD is a serious challenger to CATL in the LFP (lithium iron phosphate) battery market, with a 41.1% market share in China (compared to CATL’s 33.9%).

The “flood” of cheap EVs produced by BYD into the European and American markets is likely to be met with some level of protectionism (even above the recently imposed tariffs), which could hinder BYD’s growth.

But at the same time, cheap Chinese EVs are already a great success in the rest of the world, which does not have incumbents much in the way of domestic automakers to protect, including the entirety of South America, Russia, Africa, the Middle East, and Southeast Asia.

This represents several billion potential customers for BYD, living in countries eager to strike a geopolitical balance and stay on good terms with both the West and China, so it is unlikely to create too strong protectionist barriers.

And even in the EU or the USA, BYD might stay competitive, thanks to the much higher prices of local EV manufacturers compared to prices in China, as well as localization of the production out of China for these markets, like, for example, in Eastern Europe, Mexico, or Turkey.