Ultra-High Temperature Electronics

As mankind pushes its technology ever further, it keeps dealing with more and more extreme conditions, including heat. This is often handled with advanced materials like composite ceramics or special rare metals like tungsten, titanium, or rhodium (follow the links for a detailed investing guide for each metal).

Dealing with extreme conditions gets a little more complicated when electronic components get involved. A rocket titanium shell might withstand heat but will not block the heat from entering in the long run.

Most computer chips are designed to perform complex operations at the nanometer scale, making them very sensitive to changes in temperature. And while some hardening can be done, past a certain temperature threshold, no classical electric circuit can keep functioning.

To keep electronic controls in spaceships, nuclear power plants, or drilling systems, advanced cooling systems are used to shield the electronic elements from the surrounding environment.

This is why a newly developed form of digital memory that can store and write information at temperatures over 1100°F (600°C), or the melting temperature of steel, could be a game changer.

This achievement by researchers of the University of Michigan and Sandia National Laboratories’ was published in the scientific journal device, under the title “Nonvolatile electrochemical memory at 600°C enabled by composition phase separation”.

Oxygen-Based Memory

This memory method works by moving negatively charged oxygen atoms rather than electrons. Above 300°F (150°C), conventional silicon-based semiconductors start conducting uncontrollable levels of current.

The result is that in classic electronics, high temperatures can wipe out information in the device’s memory. However, oxygen ions are not affected by the heat.

How It Works

The oxygen atoms are moved between two layers in the memory—the semiconductor tantalum oxide and the metal tantalum.

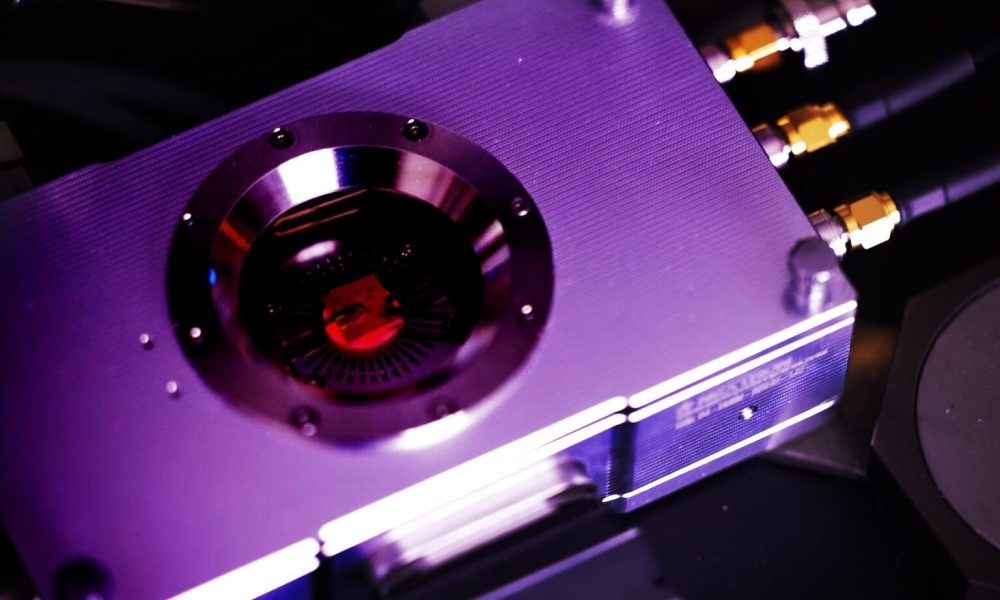

Source: Cell Device

The movement is allowed by a solid electrolyte that acts as a barrier by keeping other charges from moving between the layers. The tantalum and tantalum oxide layers do not mix, similar to oil and water, so these new layers will not revert back to the original state until the voltage is switched.

The oxygen ions are guided by a series of three platinum electrodes.

This is actually very similar to how a battery charges and discharges, except that this process optimizes the structure retention of information instead of chemical energy.

Source: Cell Device

The information states can be stored above 1100 °F for more than 24 hours.

Only An Initial Step

This scientific publication was really a proof of concept more than anything else. The initial device only retains one bit of information, but there is no theoretical limit to a much larger memory capacity.

“So far, we’ve built a device that holds one bit, on par with other high-temperature computer memory demonstrations. With more development and investment, it could in theory hold megabytes or gigabytes of data.”

Yiyang Li – U-M assistant professor of materials science and engineering

In itself, this technology is relatively similar in its performance to other materials that have been developed for re-writable, high-temperature memory (like ferroelectric memory and polycrystalline platinum electrode nanogaps).

It has, however quite a few unique advantage,s making it more likely to be worth improving:

- It can run at lower voltages than some of the leading alternatives.

- It can provide more analog states for in-memory computing.

- Finer control of the oxygen gradient could enable computing inside the memory, with more than 100 resistance states rather than a simple binary.

- In-memory computing could be possible, allowing for simple calculations to be performed by the memory without adding a classical silicon-based chip.

High-Temperature AI?

Such analog capacity with complex data encoding instead of the simpler 0 & 1 of binary could help drastically reduce power consumption.

This could be a game changer for using anything close to AI technology in high-temperature environments. Conventional computing would be too power consuming, itself a source of heat that is sometimes difficult to deal with in normal conditions. Doing so in 500-600°C conditions is nearly impossible.

“There’s a lot of interest in using AI to improve monitoring in these extreme settings, but they require beefy processor chips that run on a lot of power, and a lot of these extreme settings also have strict power budgets.

In-memory computing chips could help process some of that data before it reaches the AI chips and reduce the device’s overall power use.”

Alec Talin – Senior scientist in the Chemistry, Combustion, and Materials Science Department at Sandia National Laboratories

Limitations

One major limitation of this technology is that it only works at high temperatures. New information can only be written on the device above 500°F (250°C).

So, if the memory needs to be used in both high and low temperatures, this could be a serious issue. And while the researchers suggest a heater could solve the problem for devices that must also work at lower temperatures, this is likely not ideal.

Applications

This sort of high-temperature memory and electronic systems would be ideal for measuring data and doing computation in extreme environments.

For example:

- Aerospace Engineering: In jet engines, where internal temperatures can be extremely high, this memory technology could enable onboard data logging and real-time monitoring systems to function reliably without the need for extensive cooling mechanisms.

- Energy Sector: Geothermal energy extraction involves equipment exposed to high subterranean temperatures. Implementing this heat-resistant memory could enhance the durability and efficiency of downhole monitoring instruments, leading to more effective resource management.

- Industrial Manufacturing: Processes such as metal forging and glass production operate at elevated temperatures. Integrating this memory technology into control systems could improve process monitoring and automation, reducing downtime and maintenance costs.

- Space Exploration: On planets with extreme surface temperatures, like Venus, traditional electronics fail. This advancement could facilitate the development of probes and rovers capable of conducting extended missions in such harsh conditions, expanding our exploration capabilities.

- Nuclear Energy: Components are subjected to intense heat and radiation. Utilizing this robust memory could improve the resilience and longevity of reactor monitoring systems, contributing to safer and more efficient energy production.

Tantalum Electronic Company

Vishay Intertechnology

Vishay Intertechnology, Inc. (VSH +0.05%)

As tantalum-based electronics are finding new applications for high-temperature conditions in advanced technology like aerospace and geothermal energy, current leaders in the segment might benefit in the long term.

Tantalum is currently mostly used for capacitors, allowing for a very thin dielectric layer and providing high capacitance values in smaller case sizes.

Vishay offers surface mount and through-hole tantalum capacitors for use in automotive, military, portable consumer devices, medical devices, and many other applications.

Source: Vishay

The company also produces power electronics (silicon carbide) and other electronic components: diodes, MOSFET (metal-oxide-semiconductor field-effect transistor), optoelectronics sensors, resistors, magnets, and other types of capacitors.

The largest categories are by revenues: resistors, MOSFETs, and diodes.

This gives Vishay the “world’s largest portfolio of discrete semiconductors and passive components”.

Source: Vishay

Most of the company’s sales come from Asia (39%) and Europe (35%), with manufacturing facilities in North America, Asia, and Europe.

The company’s expertise in producing electronics made of electronic material will be an asset as the industry is expanding beyond silicon chips and new materials.

The company is currently undergoing a restructuring program, closing 3 facilities by the end of 2026 and reducing headcount by 6%, in order to save $23M annualized. At the same time, it is expanding production where needed, with a $2.6B investment in capacity expansion over the next 4 years. This should be compared to a revenue of $720M in Q3 2024, and a policy of returning to shareholders around $100M.

Overall, Vishay’s manufacturing expertise in complex electronic components in power and semiconductor applications, using exotic metals like tantalum, should come in handy in growing its sales from the development of renewables, 5G telecoms, EVs, and aerospace.