Making Electronic Devices Flexible

With smartphones, we have become used to carrying electronics with us all the time. This is, however, still done with a bulky block of metal and plastic, which, if anything, is getting bigger and heavier every year.

The next step would be to incorporate electronic devices in our attire more seamlessly. This has already started with wearable electronics like smartwatches and other health-focused wearables.

One step further would be to integrate electronics into our clothing directly. But for that, it would need to be very flexible and lightweight. There has been solid progress made in that direction:

So, if screens, batteries, and even processors are now flexible and bendable, what is still blocking us from having wearables integrated into our clothing? Powering them all is still a serious roadblock.

But this might change, thanks to a discovery by Korean researchers at the Daegu Gyeongbuk Institute of Science and Technology (DGIST), Hannam University, Yonsei University, Korea Advanced Institute of Science and Technology (KAIST), Korea Institute of Industrial Technology (KITECH) and Jeonbuk National University.

They developed a wearable energy harvester that is 280x more efficient than conventional devices, using a new type of piezoelectric energy harvester.

It was published in ACS Nano, under the title “Curvature-Specific Coupling Electrode Design for a Stretchable Three-Dimensional Inorganic Piezoelectric Nanogenerator”.

Triboelectric And Piezoelectric Devices

Energy harvesters are systems producing energy from movements. There are mostly two types, based on whether they work on the triboelectric effect or piezoelectric effect.

Triboelectric generators are what is generally called electrostatic, or what happens when two objects touch or slide against each other. This can generate some electricity but is often too weak to power electronics.

Piezoelectric is the effect of generating electricity in response to mechanical stress like bending, squeezing, etc. Until now, most piezoelectric energy harvesters have been made using organic or composite-based piezoelectric materials, which have low energy efficiency.

Pr Jang’s team was using another type of material: lead zirconate titanate (PZT).

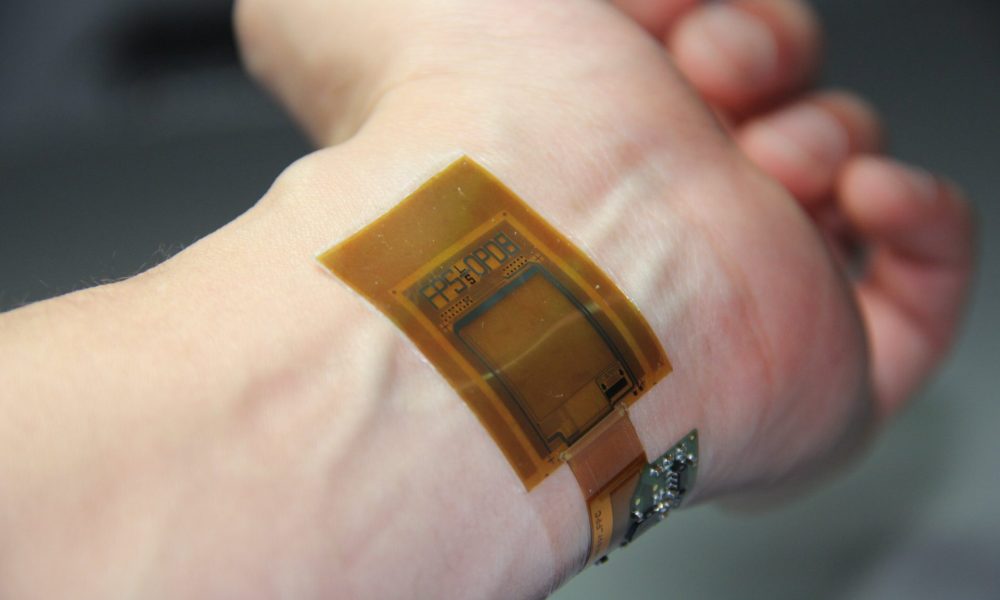

Source: DGIST

PZT Piezoelectric Generator

PZT has long been known to have excellent piezoelectric performance, but it is also hard and brittle. Therefore, using it in stretchable devices and counting on movement to generate power was unlikely to create a durable generator for wearables.

So, the researchers looked at how to design a PZT-based 3D structure that would be insensitive to deformation and guarantee stretchability while keeping the piezoelectric capability.

The first step was to create a curved electrode with a convex shape that produces power when stretched.

Source: ACS Nano

They then assemble strings of these electrodes into each other, similar to the mesh of a fabric or a wicker basket.

Source: ACS Nano

Ironing Out Problems

Because the electrodes are interlaced, they could easily cancel each other out. To avoid this, the electrodes were divided into convex and concave regions according to the direction of the induced output voltage.

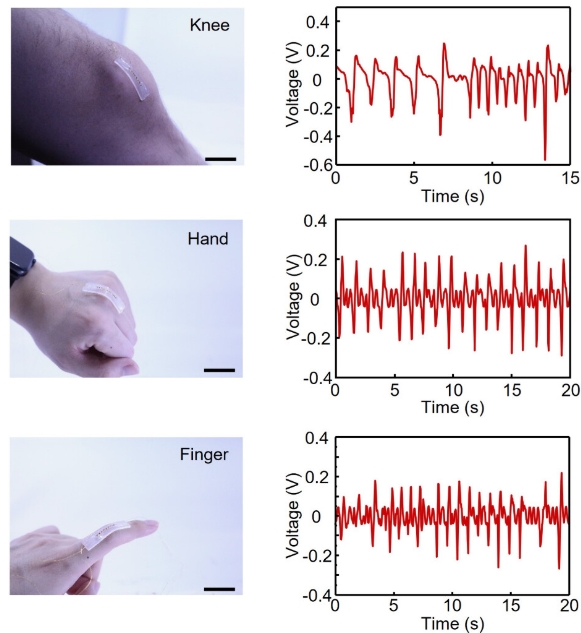

The current can be created by any motion of the body, as tested by the researchers on the knee, hand, or even fingers.

Source: ACS Nano

This created a very efficient piezoelectric generator, displaying both extreme stretchability and the highest current density for any device of this type.

Source: ACS Nano

“Developing this highly efficient stretchable piezoelectric energy harvester technology is a major achievement of this research. We expect this technology to become useful after commercialization and lead to the practical use of wearable energy harvesters.”

Pr. Kyung-In Jang – DGIST Department of Robotics and Mechatronics Engineering

Applications

Wearables

The most direct application would be to power electronics integrated into clothing when we move, such as while walking.

This could be useful for wearable devices, especially health monitoring devices that could then not be reliant on regular battery charging.

Medical Implants

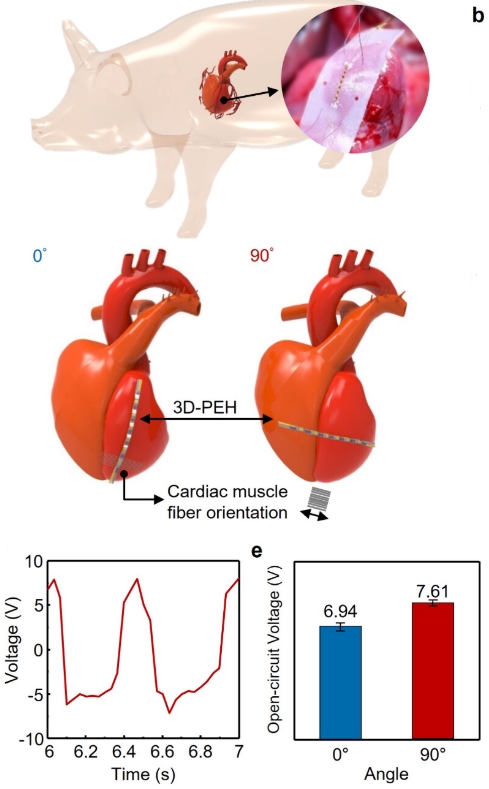

One specific type of implant could greatly benefit from this sort of generator: heart implants.

The heart is moving and contracting constantly, which can provide a stable energy source for such medical implants.

The researchers tested the concept by encapsulating the generator in encapsulated in a polyimide film. This was required to effectively isolate the PZT from biofluids and tissues, as PZT can be toxic.

Source: ACS Nano

Military

Another application could be in the military, with infantry increasingly dependent on power-hungry sensors, communications, electronic warfare, etc.

And it is hardly practical for combat units to be expected to navigate a tangle of cables and batteries. At the same time, they already have to handle their weapon, ammunition, telecom solution, etc. A piezoelectric generator directly connected to flexible electronics in the soldiers’ uniform could be a good alternative.

Investing In Wearables

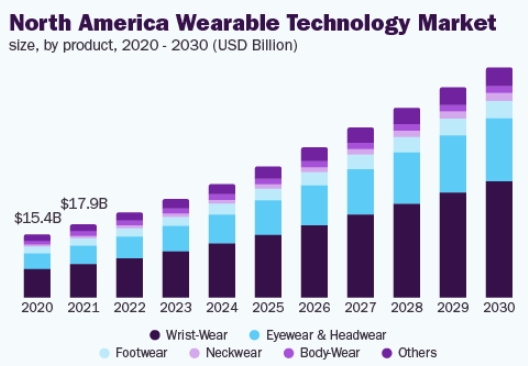

Wearable technology is expected to grow by 14.6% CAGR until 2030, from $61.2B in 2022.

Source: Grand View Research

You can invest in wearable-related companies through many brokers, and you can find here, on securities.io, our recommendations for the best brokers in the USA, Canada, Australia, the UK, as well as many other countries.

If you are not interested in picking specific companies, you can also look into ETFs like the iShares U.S. Medical Devices ETF (IHI) or the SPDR S&P Health Care Equipment ETF (XHE), which will provide a more diversified exposure to capitalize on the growing wearable and medical device industry.

You can also consult our article “Top 6 Medical Devices Stocks“.

Wearables Company

Building Wearables

One way to build flexible electronics is by using polymers. Another way to do this is to use a very flexible and non-toxic metal, gallium, which we discussed in a dedicated investment report.

Solar energy, in addition to the piezoelectric effect, could also charge flexible wearables. This could be achieved either by using perovskite solar cells or ultra-thin organic photovoltaic technology.

Koninklijke Philips N.V.

Koninklijke Philips N.V. (PHG +0.36%)

Philips is a well-known small electronics consumer brand (shavers, electric toothbrushes), equally active in healthcare. It was the #1 for MedTech patent filing in Europe for 2022.

It is active in connected medical products, from wearables to imaging, respirators, or medical robots. The company is also active in semiconductors (including maglev technology) and high-tech/robotics/automation.

Source: Philips

Philips’ wearables offer covers cardiac, respiratory, and activity metrics. Its sensors can be integrated into smartwatches, health monitors, medical patches, and activity trackers.

Regarding wearables, Philips favors a partnership solution, where it develops for third parties “their” connected IoT (Internet of Things) medical devices fully compatible with the rest of Philips’ solutions. In that context, it offers its clients prototyping, regulatory advising, end-to-end product development, and industrial-scale production.

This makes Philips a technology-focused company and a likely candidate for quickly integrating innovations like flexible piezoelectric generators into existing medical devices.

In 2023, Philips’s devices were directly affecting 1.82 billion people.

The company wants to create a fully integrated digital healthcare environment, where sensors match devices, and then use multiple connectivity solutions to integrate into the Philips HealthSuite Cloud solution and allow for in-depth data analytics.

Source: Philips

As a MedTech industry supplier, Philips is not as visible in the sector as other more prominent companies. However, it is an expert in building high-performance electronic devices and sensors, often pushing the boundaries of what’s possible in its niche in healthcare and wearables.

With wearables increasingly integrated into healthcare and medical protocols, the Healthcare segment of Philips will likely grow as a part of the conglomerate.